Ice Houses

- Page ID

- 50859

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\dsum}{\displaystyle\sum\limits} \)

\( \newcommand{\dint}{\displaystyle\int\limits} \)

\( \newcommand{\dlim}{\displaystyle\lim\limits} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\(\newcommand{\longvect}{\overrightarrow}\)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)What do these three, culturally diverse buildings have in common?

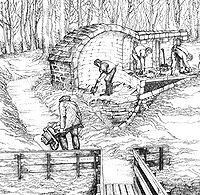

They are all icehouses, used to store ice for food preservation and other purposes during warmer months. Closer to home in the US is the icehouse at Ambler's Texaco, the longest operating service station on historic Route 66 in Dwight, Illinois, making it a "full service" station:

The ice house is a 24 foot (7.3 m) by 16 foot (4.9 m) wood clad frame building with sawdust insulation to preserve the ice, probably built in the 1930s. There was a small pond about 200 feet away where operators cut ice, and stored it in the building until sale.[5]

Storing Heat or "Cold"

Water based technology for thermal energy storage is made practical by the large heat of fusion or enthalpy of fusion of water, which is the heat energy absorbed by a solid when it melts; it is usually quoted on a molar basis. (The word fusion means the same thing as “melting.”) When 1 mol of ice, for example, is melted, we find from experiment that 6.01 kJ are needed. The molar enthalpy of fusion of ice is thus +6.01 kJ mol–1, and we can write

\[\ce{H2O (s) -> H2O (l)}\nonumber\]

(0°C) ΔHm = 6.01 kJ mol–1

How much would it cost in electricity to produce the ice in the Ambler Ice House? Would ice houses be an environmentally or economically viable source of ice today? Assuming it is stacked about 2.5 m high, the ice house holds 7.3 m x 4.9 m x 2.5 m = 89 m3 of ice. Since ice has a density of 0.92 g/cm3, which we'll round to 1 g/cm3, so 1 m3 of ice is 1m3x (102cm/m)3x 1 g/cm3= 106 g. The building holds 89x106 g of ice.

The energy equivalent is 6.01 kJ mol–1 / 18 g mol–1 x 89x106g= 3 x 107kJ. Since a kilowatt hour (kWh) of electricity is 3600 kJ, this is 8.3 x 103 kWh. The average cost of residential electricity was 12¢/kWh (DOE) in the U.S. in April 2009, so it would take $990 worth of electricity to make this much ice from water at 0 °C, assuming a 100% efficient freezer.

One metric ton of water, just one cubic meter, can store 334 MJ (317 k BTUs, 93kWh or 26.4 ton-hours). In fact, ice was originally transported from mountains to cities for use as a coolant, and the original definition of a "ton" of cooling capacity (heat flow) was the heat to melt one ton of ice every 24 hours. This is the heat flow one would expect in a 3,000-square-foot (280 m2) house in Boston in the summer. This definition has since been replaced by less archaic units: one ton HVAC capacity = 12,000 BTU/hour. Either way, an agreeably small storage facility can hold enough ice to cool a large building for a day or a week, whether that ice is produced by anhydrous ammonia chillers or hauled in by horse-drawn carts.

[edit] Air conditioning The most widely used form of this technology is in large building or campus-wide air conditioning or chilled water systems. Air conditioning systems, especially in commercial buildings, are the most significant contributors to the peak electrical loads seen on hot summer days. In this application a relatively standard chiller is run at night to produce a pile of ice. Water is circulated through the pile during the day to produce chilled water that would normally be the daytime output of the chillers.

A partial storage system minimizes capital investment by running the chillers 24 hours a day. At night they produce ice for storage, and during the day they chill water for the air conditioning system, their production augmented by water circulating through the melting ice. Such a system usually runs in ice-making mode for 16 to 18 hours a day, and in ice-melting mode for 6 hours a day. Capital expenditures are minimized because the chillers can be just 40 to 50% of the size needed for a conventional design. Ice storage sufficient for storing half a day's rejected heat will do.

A full storage system minimizes the cost of energy to run the system by shutting off the chillers entirely during peak load hours. Such a system requires chillers somewhat larger than a partial storage system, and a larger ice storage system, so that the capital cost is higher. Ice storage systems are inexpensive enough that full storage systems are often competitive with conventional air conditioning designs.[citation needed]

The efficiency of air conditioning chillers is measured by their coefficient of performance (COP). In theory, thermal storage systems could make chillers more efficient because heat is discharged into colder nighttime air rather than warmer daytime air. In practice, this advantage is overcome by the heat losses while making and melting the ice.

There are still some advantages to society from air conditioning thermal storage. The fuel used at night to produce electricity is a domestic resource in most countries, so that less imported fuel is used. This process also has been shown in studies to significantly reduce the emissions associated with producing the power for air conditioners, since inefficient "peaker" plants are replaced by low emission base load facilities in the evening. The plants that produce this power are often more efficient than the gas turbines that provide peaking power during the day. And because the load factor on the plants is higher, fewer plants are needed to service the load.

A new twist on this technology uses ice as a condensing medium for refrigerant. In this case, regular refrigerant is pumped to coils where it is used. Instead of needing a compressor to convert it back in to a liquid however, the low temperature of the ice is used to chill the refrigerant back in to a liquid. This type of system allows existing refrigerant based HVAC equipment to be converted to Thermal Energy Storage systems, something that could not previously be easily done with chill water technology. In addition, unlike water-cooled chill water systems that do not experience a tremendous difference in efficiency from day to night, this new class of equipment typically displaces daytime operation of air cooled condensing units. In areas where there is a significant difference between peak daytime temperatures and off peak temperatures, this type of unit is typically more energy efficient than the equipment it is replacing.[2]

When heat energy is supplied to a solid at a steady rate by means of an electrical heating coil, we find that the temperature climbs steadily until the melting point is reached and the first signs of liquid formation become evident. Thereafter, even though we are still supplying heat energy to the system, the temperature remains constant as long as both liquid and solid are present. Only when the last vestiges of the solid have disappeared does the temperature start to climb again.

This macroscopic behavior demonstrates quite clearly that energy must be supplied to a solid in order to melt it. On a microscopic level melting involves separating molecules which attract each other. This requires an increase in the kinetic energy of the molecules, and the necessary energy is supplied by the heating coil.

Selected molar enthalpies of fusion are tabulated below. Solids like ice which have strong intermolecular forces have much higher values than those like CH4 with weak ones.

When a liquid is boiled, the variation of temperature with the heat energy supplied is similar to that found for melting. When heat is supplied at a steady rate to a liquid at atmospheric pressure, the temperature rises until the boiling point is attained. After this the temperature remains constant until the enthalpy of vaporization has been supplied. Once all the liquid has been converted to vapor, the temperature again rises. In the case of water the molar enthalpy of vaporization is 40.67 kJ mol–1. In other words

\[\ce{H2O (l) -> H2O (g)}\nonumber\]

(100°C) ΔHm = 40.67 kJ mol–1

| Substance | Formula | ΔH(fusion) / kJ mol1 |

Melting Point / K | ΔH(vaporization) / kJ mol-1 | Boiling Point / K | (ΔHv/Tb) / JK-1 mol-1 |

|---|---|---|---|---|---|---|

| Neon | Ne | 0.33 | 24 | 1.80 | 27 | 67 |

| Oxygen | O2 | 0.44 | 54 | 6.82 | 90.2 | 76 |

| Methane | CH4 | 0.94 | 90.7 | 8.18 | 112 | 73 |

| Ethane | C2H6 | 2.85 | 90.0 | 14.72 | 184 | 80 |

| Chlorine | Cl2 | 6.40 | 172.2 | 20.41 | 239 | 85 |

| Carbon tetrachloride | CCl4 | 2.67 | 250.0 | 30.00 | 350 | 86 |

| Water* | H2O | 6.00678 at 0°C, 101kPa 6.354 at 81.6 °C, 2.50 MPa |

273.1 | 40.657 at 100 °C, 45.051 at 0 °C, 46.567 at -33 °C |

373.1 | 109 |

| n-Nonane | C9H20 | 19.3 | 353 | 40.5 | 491 | 82 |

| Mercury | Hg | 2.30 | 234 | 58.6 | 630 | 91 |

| Sodium | Na | 2.60 | 371 | 98 | 1158 | 85 |

| Aluminum | Al | 10.9 | 933 | 284 | 2600 | 109 |

| Lead | Pb | 4.77 | 601 | 178 | 2022 | 88 |

*http://www1.lsbu.ac.uk/water/data.html

Heat energy is absorbed when a liquid boils because molecules which are held together by mutual attraction in the liquid are jostled free of each other as the gas is formed. Such a separation requires energy. In general the energy needed differs from one liquid to another depending on the magnitude of the intermolecular forces. We can thus expect liquids with strong intermolecular forces to have larger enthalpies of vaporization. The list of enthalpies of vaporization given in the table bears this out.

Two other features of the table deserve mention. One is the fact that the enthalpy of vaporization of a substance is always higher than its enthalpy of fusion. When a solid melts, the molecules are not separated from each other to nearly the same extent as when a liquid boils. Second, there is a close correlation between the enthalpy of vaporization and the boiling point measured on the thermodynamic scale of temperature. Periodic trends in boiling point closely follow periodic trends in heat of vaporization. If we divide the one by the other, we find that the result is often in the range of 75 to 90 J K–1 mol–1. To a first approximation therefore the enthalpy of vaporization of a liquid is proportional to the thermodynamic temperature at which the liquid boils. This interesting result is called Trouton’s rule. An equivalent rule does not hold for fusion. The energy required to melt a solid and the temperature at which this occurs depend on the structure of the crystal as well as on the magnitude of the intermolecular forces.

From ChemPRIME: 10.9: Enthalpy of Fusion and Enthalpy of Vaporization

References

- en.Wikipedia.org/wiki/Ice_house_(building)

- en.Wikipedia.org/wiki/Ice_house_(building)

- en.Wikipedia.org/wiki/Ice_house_(building)

- en.Wikipedia.org/wiki/Ambler%27s_Texaco_Gas_Station

- gis.hpa.state.il.us/hargis/PDFs/218435.pdf

Contributors and Attributions

Ed Vitz (Kutztown University), John W. Moore (UW-Madison), Justin Shorb (Hope College), Xavier Prat-Resina (University of Minnesota Rochester), Tim Wendorff, and Adam Hahn.