2.2: Distillation

- Page ID

- 135943

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)Distillation is a purification technique for a liquid or a mixture of liquids. We utilize the difference in  boiling points of liquids as a basis of separation. The core of a distillation process, is selective evaporation and condensation of particular components. Our overall goal is to evaporate and condense only one component from a mixture, but to attain this goal, we must allow many, many cycles of evaporation and condensation to take place. This process gradually enriches the vapor phase in favor of the most volatile component. After a sufficient number of evaporation and condensation cycles have taken place, the final condensate contains a liquid that is en- riched in the more volatile component.

boiling points of liquids as a basis of separation. The core of a distillation process, is selective evaporation and condensation of particular components. Our overall goal is to evaporate and condense only one component from a mixture, but to attain this goal, we must allow many, many cycles of evaporation and condensation to take place. This process gradually enriches the vapor phase in favor of the most volatile component. After a sufficient number of evaporation and condensation cycles have taken place, the final condensate contains a liquid that is en- riched in the more volatile component.

Distillation is easier to understand if we envision a spesific mixture of two liquids, say diethyl ether and ethanol. The boiling points of the two liquids are 36°C and 78°C, respectively. When we boil this mixture, we observe the following: the entire mixture (both compounds) boils, but the vapor phase is enriched in the more volatile component (diethyl ether). As this vapor mixture rises, cools, and condenses, the resulting liquid is enriched in diethyl ether too. If we attach a column to the flask so that the vapor enters this column, the condensing liquid will be heated by rising vapors, and it will boil again producing a vapor that is even more enriched in diethyl ether. The higher the column, the more times this cycle of evaporation-condensation can be repeated, and the higher up we sample the vapor, the more enriched the vapor phase will be in the more volatile component (diethyl ether). Ideally, with a long enough column, one could obtain a vapor that is nearly pure diethyl ether, and leave behind a liquid that is nearly pure ethanol, the less volatile component.

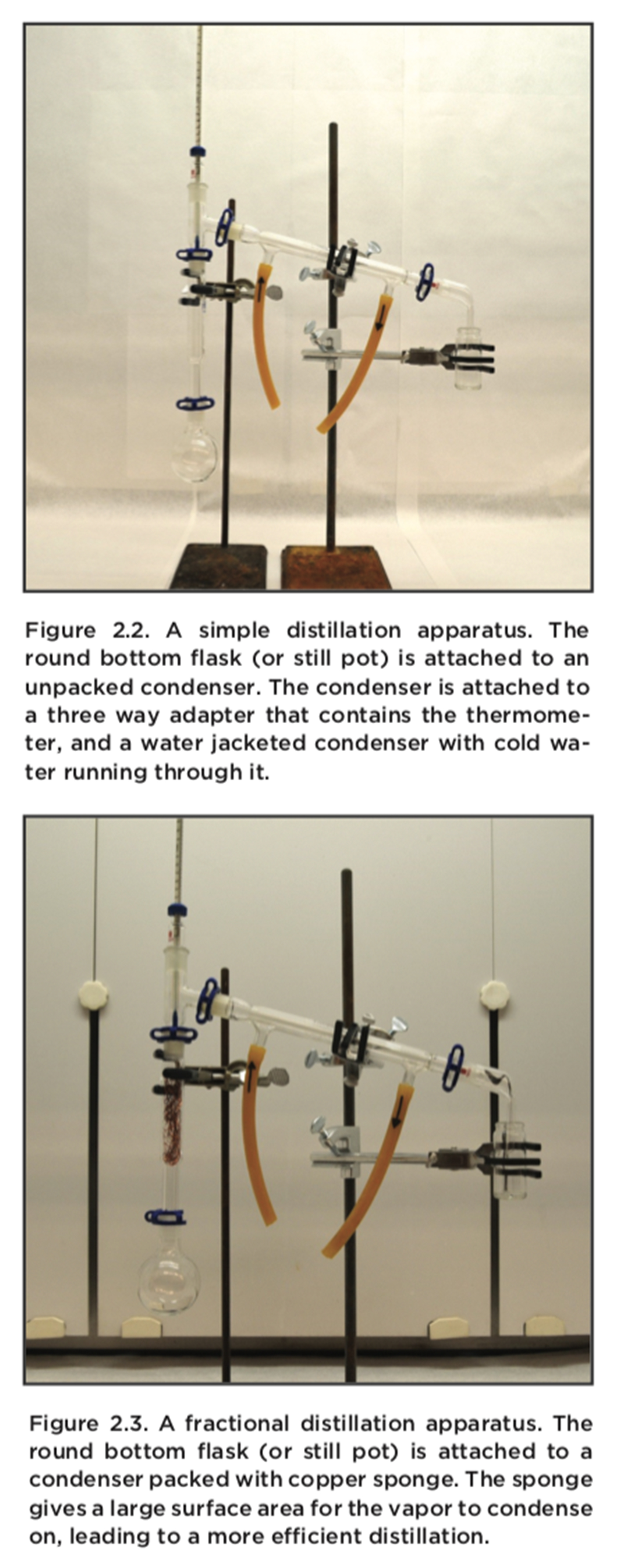

Let us discuss a typical distillation apparatus (shown above) We start with a flask containing the solution (often called a still pot), which is heated. You can see from our discussion above, that a key feature of a distillation apparatus must be a column, where many cycles of condensation and evaporation can take place. The column can be just a short tube (an “unpacked” col- umn), which is the basis of a simple distillation. This is typically less efficient. The column can be packed with an inert material, which is the basis of a fractional distillation, and typically constitutes a more efficient distillation. The inert material, such as copper sponge or glass beads, provides a large surface area, thus allowing many more evaporation-condensation cycles.

The column is attached to an adapter. In the top of this connector is the thermometer, which is used to read the temperature of the vapor, just as it condenses. The temperature reading is important, because, at normal conditions, the temperature of the vapor passing through is the same as the boiling point of the substance being collected. Vapor that passes the thermometer condenses in the condenser, a double-walled tube that is cooled by water flowing through the outer layer, and drips into the receiver.

Before moving on, let us look at benefits and drawbacks to a simple distillation versus a fractional distil- lation. We have already said that the simple distillation is less efficient at separating liquids, because there is a smaller surface area inside the column, but it is usually much faster. For mixtures that contain only one volatile component, a simple distillation can be more than sufficient. The fractional distillation is more efficient, and is suited for mixtures of volatile liquids. The closer the difference in the boiling points, the more demanding the distillation. The drawback is that fractional distillations typically take longer, because we want to achieve pseudo-equilibrium between vapor and liquid throughout this system. Slow boiling and ample time is important to achieve this goal.

Sounds easy, right? What can go wrong? Poor separation is the most likely problem you will face. This means that the fractions obtained are impure, and often contain traces of the other liquids found in the original mixture. We will assume that we are performing a fractional distillation, and that we have several liquids that must be separated. Let us look at some of the technical aspects that are important for acceptable separation, and some key features for the assembly of the distillation apparatus.

Troubleshooting Distillation

- The distillation result is poor: the fractions obtained are not of acceptable purity.

Typical problems: Distillation too fast. The components require time to separate. We need many evaporation-condensation cycles for good separation, and pseudo-equilibrium between vapor and liquid throughout the system. If we supply too much energy to the system (i.e., too much heat), we allow even the less volatile components enough energy to keep evaporating. The vapor phase is therefore not enriched with the more volatile component.

A certain amount of time is also required. Allowing the mixture to gently reflux for a while (30 minutes) before gradually increasing the energy supplied to the system through heating is typically a good strategy.

- You collect distillate, but the temperature reading does not correspond to the boiling point of the component. Typically, the temperature reading is much lower.

Typical problems: The thermometers found in a standard organic chemistry teaching laboratory is not of the highest quality, and they are often mistreated through many terms. They should therefore be calibrated by reading boiling distilled water. Furthermore, the location of the thermometer bulb is essential. If the bulb is too high, the vapor condenses before the thermometer can read the temperature. Typically, the bulb should rest right above the lowest part of the adapter (see the set-up above).

- Even though the liquid in the still pot is boiling, no distillate is being collected.

Typical problems: Insulation is a key feature to consider whenever distillation does not occur. Have a look at the entire apparatus and see where the vapor has reached, by looking for drops of condensation. Insulating the top of the still pot, as well as the column and top of the three-way adapter can be beneficial. Remember that the vapor must heat the glassware to the boiling point of the condensing liquid before it can evaporate again and rise through the apparatus. Because the distillation is performed in a fume-hood, the constant air-flow inside the hood also cools the apparatus.

- Nothing distills but the amount of liquid in the still pot mysteriously goes down.

Typical problems: There is a leak in the system, or several leaks. The vapor is escaping though openings between joints. Make sure that all joints are properly sealed.