2.1: RECRYSTALLIZATION

- Page ID

- 135942

Recrystallization is a laboratory technique for purifying solids. The key features of this technique is causing a solid to go into solution, and then gradually allowing the dissolved solid to crystallize. Sounds easy, doesn’t it? It is actually a very challenging process to get completely right. The goal, is to obtain a compound in high purity as uniform crystals. Recrystallization is therefore a purification technique.

The key features necessary for a successful recrystallization process, are a very controlled temperature decrease and sufficient time. Because most solids have a better solubility at higher temperatures, we can sat- urate or almost saturate a solution at high temperature (usually the boiling temperature of the solvent), and then slowly allow the solution to reach room temperature. As the temperature starts to decrease, so does the solubility of the compound. As the solubility decreases, the solution at some point becomes supersaturated and crystals will start to form.

Before we move on, let me address the main problem associated with crystallization: the formation of precipitate, versus crystals. A precipitate is simply a mixture of compounds in the solution that crash out. This can happen for a variety of reasons, but a student may have taken the very hot solution and placed it directly on a cold surface to cool (a process called “shock cooling”) or even plunged the hot solution into an ice bath. A precipitate may not pure, because it can contain several compounds. Crystals, however, are often composed solely of one compound. It is very easy to get a precipitate, but very difficult to get crystals.

We already mentioned temperature and time being key factors for successful recrystallization. Precipitation typically occurs when the temperature has not been lowered gradually. Furthermore, we must not disturb the solution (or its container) as it cools (even though it is tempting). Disturbing the solution can break up any seed crystals6 that have started growing.7

6 A seed crystal is a small piece of crystal from which crystallization occurs.

7 A typical challenge in a research laboratory involves recrystallization to form a crystal suitable for x-ray analysis. Such crystals are often referred to as single crystals, and not only must they be completely pure, but also the crystal lattice and growth must be highly ordered. This task can be monumental, as very small variables can be detrimental to the growth of a single crystals. During grad-school, a post-doc told me to leave the crystals growing in a room where nobody ever went, as even the vibrations of footsteps or laboratory equipment could be detrimental.

Please also note that some compounds simpl crystallize more easily than others. More rigid molecules are, as a rule, easier to crystalize.8 Rigid, in this context, mean compounds that contain fewer bond capable of undergoing internal rotation, so that there are fewer possible conformers possible.

Let us go through a recrystallization process, focusing on technical aspects and trouble shooting.

How to perform a recrystallization:

- The crude impure solid is dissolved in hot solvent. If some solid remains undissolved after adding solvent, it is likely to be an impurity and should be removed by filtrering the (hot!) solution.

Typical problems: Adding too much solvent so that the product does not crystallize later. Filtering the hot solution too slowly so that the solvent cools and the solid starts crystallizing in the funnel and/or on the sides of glassware.

- The solution is allowed to stand without being disturbed. The temperature is allowed to gradually drop, leading to growth of large crystals. The flask should not be placed on a surface (it will shock-cool the solution), but either placed in an insulated jar, or clamped.

Typical problems: Crystals do not form at all (too much solvent), precipitate forms instead of crystals (temperature has dropped too quickly, or an oil forms).

- The solution is allowed to stand until crystallization is complete.

Typical problems: Crystallization can be a slow process, and impatience can lead to low recovery.

- The solution is placed in an ice-water bath to lower the temperature even further, and allow more crystals to form. At this point, most crystals should already have formed.

- The crystals are filtered and air-dried.

How can we tell if a recrystallization has been a success? Sim- ple visual inspection is a good start: The crystals should have shiny surfaces and catch the light. They should appear uniform, and you should have crystals of similar structure and size. A melting point analysis should also show a narrower and elevated melting point range compared to the crude material.

Like any purification technique, recrystallization has some limitations. First of all the compound you crystallize should be a solid at standard conditions. Greases, waxes and oils cannot be crystallized at standard conditions. Secondly, the crude material should be mostly pure. There is not any minimum purity standard for any crude material, because the success of any recrystallization depends on the identities of the other constituents and their respective solubilities, but in general the crude material should contain about 80% of the desired compound.

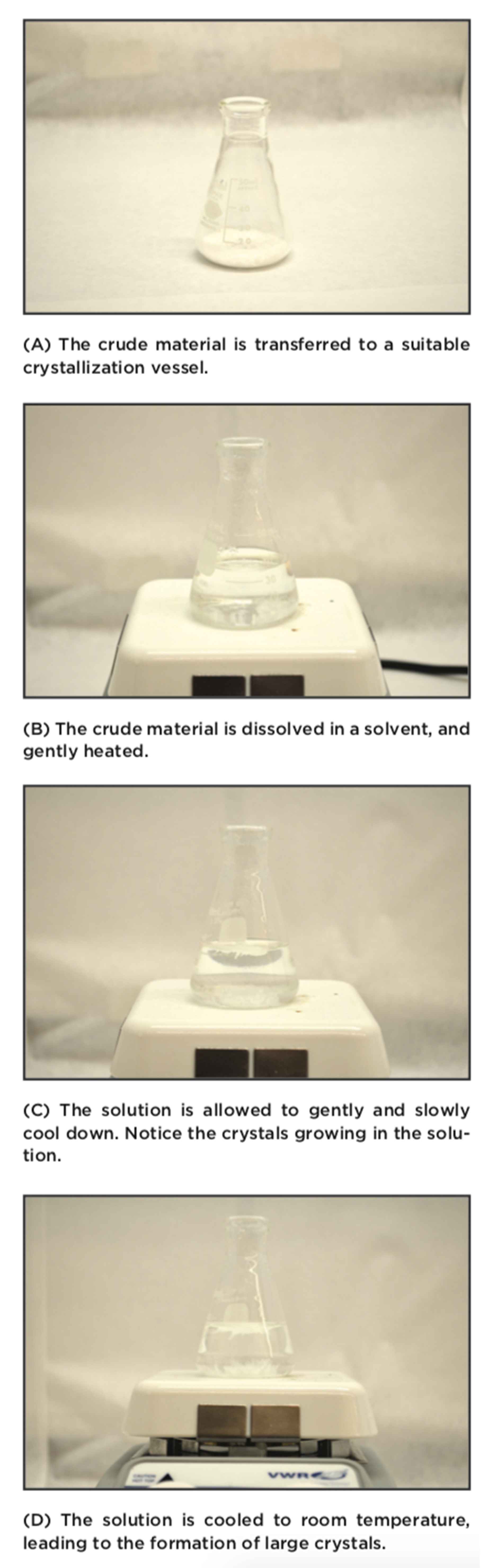

The crude material is transferred to a suitable crystallization vessel. The crude material is dissolved in a solvent, and gently heated.

The solution is allowed to gently and slowly cool down. Notice the crystals growing in the solution. The solution is cooled to room temperature, leading to the formation of large crystals.

8 I have prepared new compounds that I have tried on and off to recrystallize for the better part of a whole year, without success.