13.3: Life Cycles in Industrial Ecosystems

- Page ID

- 285374

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)In conventional industrial systems, a product is manufactured and marketed after which the vendor forgets about it (unless some product defect, such as sticking accelerator pedals on an automobile forces a recall). In a system of industrial ecology, however, the entire life cycle of the product is considered. An important aspect of such a consideration is the life-cycle assessment. The overall goal of a life-cycle assessment is to determine, measure, and minimize environmental and resource impacts of products and services.

An important decision that must be made at the beginning of a life-cycle assessment is determination of the scope of the assessment. Parameters included in the scope include the time period to be considered, the area (space) to be considered, and the kinds of materials, processes, and products that will go into the assessment. As an example, consider the chemical synthesis of an insecticide that releases harmful vapors and generates significant quantities of waste material. A narrowly focussed life-cycle assessment might take account of control measures to capture released vapors and the best means of disposing of the waste byproducts. A broader scope would consider a different synthetic process that might not cause the problems mentioned. An even broader scope might consider whether or not the insecticide even needs to be made and used; perhaps there are more acceptable alternatives to its use.

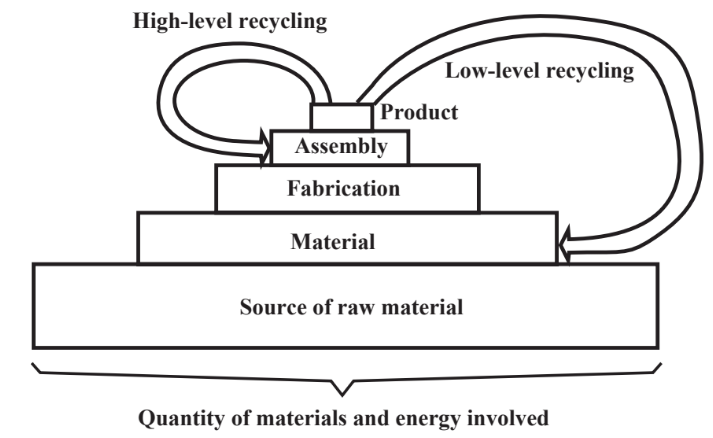

Life cycle assessment involves an inventory analysis to provide information about the consumption of material and release of wastes from the point that raw material is obtained to make a product to the time of its ultimate fate, an impact analysis that considers the environmental and other impacts of the product, and an improvement analysis to determine measures that can be taken to reduce impacts. A life-cycle assessment gives a high priority to the choice of materials in a way that minimizes wastes. It considers which materials and whole components can be used or recycled. And it considers alternate pathways for manufacturing processes or, in the case of chemical manufacture, alternate synthesis routes.

In doing life-cycle assessments it is useful to consider the three major categories of products, processes, and facilities, all of which have environmental and resource impacts. Products are obviously the things and commodities that consumers use. They are discussed further in Section13.4. Processes refer to the ways in which products are made. Facilities consist of the infrastructural elements in which products are made and distributed.

Some of the greater environmental impacts from commerce result from the processes by which items are made. An example of this is paper manufacture. The environmental impact of the paper product tends to be relatively low. Even when paper is discarded improperly, it does eventually degrade without permanent effect. But the process of making paper, beginning with harvesting of wood and continuing through the chemically intensive pulping process and final fabrication has significant environmental impact. In addition to potential air and water pollution, paper making consumes energy and requires large amounts of water. Processes can be made much more environmentally friendly by application of the principles of industrial ecology enabling maximum recycling of materials that otherwise would have significant pollution potential.

The impact of facilities can vary over a wide range. A specialized facility such as a steel mill or petroleum refinery can have a significant environmental impact. Abandoned sites of these facilities can be blighted and difficult and expensive to restore for some other use. (The term

“brownfields” is sometimes used to describe sites of abandoned industrial facilities, and restoration of blighted “brownfields” is often a major goal of urban renewal projects.) One of the more challenging kinds of facilities to decommission are sites of nuclear power reactors in which there is a significant amount of radioactivity to deal with in dismantling and disposing of some of the reactor components. The impact of facilities can be minimized by designing them with future use and eventual decommissioning in mind. Typically, well designed commercial buildings may have a number of lives during which they are used by a sequence of enterprises. A key aspect of abuilding destined for multiple use is structure flexibility so that it can easily be rearranged for new uses.

Product Stewardship

The control of the life cycle of products that are sold is difficult. Attempts are made to exercise some degree of control by facilitating return of spent products. For example, laser printer cartridges commonly come with a return address and postage to return the used cartridge to the manufacturer. Another approach is to pay for the return of spent products. The price of a new automobile battery is commonly increased to cover a modest refund paid upon return of the spent battery. Automobile tires have a financial disincentive for recycling in that the customer is commonly charged a disposal fee.

The success rate with these kinds of measures is mixed. Automobile tires are almost invariably mounted at a dealer’s place of business, so customers pay the disposal fee in order to not be responsible for used tire disposal. Customers who install their own batteries usually turn in the old ones because they do not have a good disposal option. The return rate with printer cartridges is probably lower because people do not want to go to the trouble to mail them back.

The rate of return of items at the end of their life cycles is higher in companies and institutions where returns are more readily facilitated. The presence in a large office of a recycled paper bin or an “out box” where returned laser printer cartridges can be dropped for mailing certainly increases the recycle rate of these items. One key to recycling is in product stewardship where there are clear lines of accountability for items and materials. A good way to ensure product stewardship for things such as office equipment is through the leasing of equipment. In such a case, the concern holding the lease, rather than the user, is responsible for the ultimate fate of the item. The same approach can even be used with some kinds of materials, such as activated carbon used in a water treatment plant. Here the concern leasing the carbon retains ownership and is responsible for picking up the spent material for recycling. Another way to help ensure product stewardship through the consumer sector is by charging deposits on items and refunding the deposit upon return for recycling.