Hans-Gerd Janssen, Unilever Research and Development Vlaardingen, the Netherlands

Abstract

The basic principle of on-column large volume injection is very straightforward. A retention gap is installed before the analytical column. The large volume sample is than introduced directly into this retention gap using some type of an on-column injector.

Level: Basic

During introduction of the sample the temperature of the column oven is low, some 15oC below the normal boiling point of the solvent. This means that, as in the on-column injection of a standard volume, the sample is introduced in the liquid state. Discrimination or degradation is hence absent because the sample is directly introduced from the syringe into the column system without an intermediate evaporation step. It is evident that the retention gap, in order to accommodate the entire sample volume, should be sufficiently long. As a rough rule of the thumb: every microliter of sample results in an increase of the zone length of the wetted zone of roughly 20 centimetres. This means that for a 100 µl injection a retention gap of at least 20 meters is required. As the solvent plug may move along the retention gap, a safety margin of some 5 meters has to be added to this length. The use of such a long retention gap not only makes the column system expensive, it also renders evaporation very slow. Due to the long retention gap the column system has a serious flow resistance. This means that the gas flow rate through the system is low and, hence, evaporation of the solvent is slow. A second disadvantage of the on-column method for large volume injection is that in the simple set-up described above the entire volume of solvent has to be discharged from the system via the detector. Many of the more sensitive and/or selective GC detectors such as the nitrogen phosphorous detector, the flame photometric detector, electron capture detector and the mass spectrometer, however, do not tolerate the introduction of large volumes of solvent.

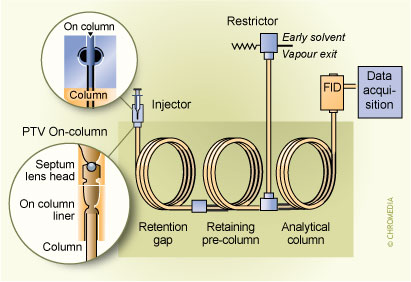

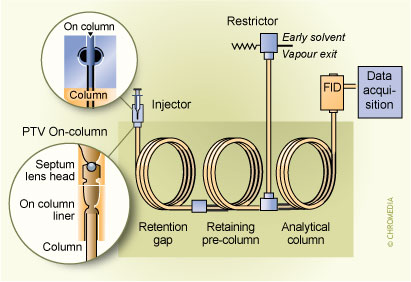

To overcome this disadvantage, systems for on-column large volume injection are very often equipped with a so-called 'early solvent vapour exit (ESVE)'. This is an additional gas exit installed between the retention gap and the analytical column. The illustration shows a schematic representation of a system for on-column large volume injection in capillary GC.

On-column LVI. A: Standard B: Retaining precolumn.

The ESVE is opened during solvent evaporation and is closed when solvent evaporation has reached completion. An advantage of the use of an ESVE is that solvent vapours no longer have to be discharged via the detector. In this way the detector is protected from large volumes of solvent vapour. Moreover, if an ESVE is used, the back pressure provided by the column system is significantly reduced, which results in a significantly higher column flow at a given inlet pressure. Evaporation of the sample solvent is hence faster. Apart from these advantages the use of an early solvent vapour exit also has several disadvantages, these include more expensive instrumentation and the greater complexity of the system.

Timing of Closure

To avoid losses of volatile sample constituents together with the solvent, the timing of closure of the ESVE is highly critical. This timing is so critical that a system as the one described above consisting of a retention gap, an ESVE and the analytical column can not be used for daily routine analyses. To make the timing of closure of the ESVE less critical and to avoid losses of volatiles, a so-called 'retaining precolumn' has to be installed between the retention gap and the ESVE outlet. This is a short piece (approximately 2 meters) of the analytical column. This column, in contrast to the retention gap, does contain stationary phase, it provides some separation between the wide solvent peak and the volatile components. The moment of closing of the ESVE outlet is now less critical and losses of volatile components are reduced. Still a certain minimum difference in boiling point between the solvent and the first components of interest is required. Quantitative recovery of n-C7 in a large volume injection using hexane as the solvent is impossible. For a really reliable method a boiling point difference of at least some 35oC to 40oC is required. In previous chapters it is already stated that from the fundamental point of view, on-column injection is superior to any of the other sample introduction techniques in capillary GC. This is because with on-column injection the sample is transferred from the syringe directly into the column in the liquid state. No intermediate evaporation step is involved in the transfer of the sample. Sample loss by selective evaporation or by the absence of evaporation, as well as losses by adsorption or thermal degradation can hence be precluded.

Drawbacks for using on-column LVI

Despite the evident advantages of on-column sample introduction one would, for practical reasons, usually try to avoid the use of this technique, even in analyses in which only small volumes are injected. Only if each of the alternative injection techniques fails one would resort to on-column injection. This because on-column injection is less rugged, difficult to automate and because column contamination by high molecular weight impurities occurs more readily than in (hot) split and splitless or PTV injection. In principle the same remarks also hold for on-column large volume injection. From the theoretical point of view, on-column large volume injection is superior to the other methods of large volume injection. For practical reasons, however, one would again often try to avoid the use of the on-column interface in large volume injection. Contamination of the retention gap readily occurs in the on-column injection of large volumes. This results in losses of adsorptive and/or unstable components and makes it necessary to replace the retention gap and to re-optimize the time of closing the ESVE. Moreover, the various column connectors incorporated in a system for on-column large volume injection each form a potential source of leakage. The short description of the on-column method for large volume injection given here is not intended to be a detailed discussion of the principles, advantages and disadvantages and applications of on-column large volume sampling. Its only aim is to give the reader an impression of the on-column large volume injection method. For a more detailed discussion of the technique as well as for further details, the interested reader is referred to literature [@].