Injection principles of capillary GC

- Page ID

- 61161

Level: Basic

The small dimensions of open tubular columns impose stringent demands on the quality of the sample and the way it is introduced onto the column.

Sampling techniques include methods for collecting gas and vapor samples from matrices which cannot be analysed directly. Methods of this type fall under the general heading of headspace analysis and often include enrichment techniques to increase the component concentrations to above the minimum detectable levels of the GC.

Any non-volatile material will accumulate at the column entrance and causes rapid deterioration of column performance. Sample preparation techniques should be applied wherever possible to eliminate non-volatile materials and to ensure that any trace components are present in sufficient quantity for their satisfactory detection and measurement.

In many applications both the sample preparation and sample introduction methods (injection mode) can be integrated into a single operation using appropriate equipment as discussed later in this chapter.

Requirements & Techniques

Capillary columns offer very high separation efficiencies. The sample (volume) capacity of capillary columns, however, is very small and column overloading can easily occur. This limited sample capacity poses a number of stringent requirements on the way the sample is introduced onto the column.

Requirements Sample Introduction:

- The injection must be fast

- The sample band must be narrow (at the column inlet)

- Small sample amount

- (vapor) volume

- sample mass

- The injection should produce no sample discrimination

- The injection should not produce sample carry-over (memory effects)

- No pollution / adsorption

There is no single sampling technique or injection mode that can meet all these requirements. This is why a number of different sampling techniques and injection modes have been developed for GC, each depending on the column type and the nature and concentration of the analytes in the sample.

Universal Injection Modes:

- Direct injection is seldom used with the exception of two cases: injection of gases with a valve and in combination with a wide-column

- Split injection: This is the most widely used injection mode in capillary GC and is suitable for 'normal' concentration ranges.

- Splitless injection for strongly diluted samples (trace analyses)

- (Cold) on-column for strongly diluted samples (trace analyses)

- (Gas) injection with sampling valves

Selective Injection Modes:

- PTV

- Head-space

- Thermal desorption

- Gas stripping techniques (‘purge-and-trap’)

- Large volume injection (LVI)

Sample Volume Capacity

The volume capacity of a column can be defined as the maximum volume of sample vapor that can be admitted to the injector before the column performance deteriorates to an unacceptable level.

The sample volume, after it has been converted to vapor in the injector, determines the time required to transfer the sample to the column and hence the initial zone occupancy width. This, however, also depends on the injector geometry and the operating conditions.

Calculation may show that the column can accept a certain volume of sample vapor to give an insignificant occupation of the column but can still give peak distortion due to overloading of the injector.

Two sample volume capacities are relevant:

- Injector volume capacity

- Column volume capacity

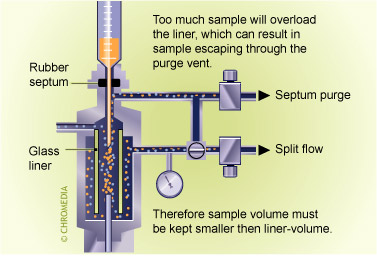

Overloading of injector liner

The sample volume capacity of a column depends on:

- Column volume

- Intrinsic column efficiency

- Retention factor

Packed columns, with their much higher stationary phase loading and large geometrical volumes yield typical sample volume capacities of several milliliters and, therefore, can easily tolerate liquid volumes of several microlitres.

For capillary columns, however, it would be almost impossible to introduce a sufficiently small volume of liquid sample onto columns smaller than 0.53 mm in diameter, assuming isothermal conditions. However, for 0.53 mm (wide-bore) columns the column volumes are sufficiently large to enable small liquid samples to be directly injected without splitting arrangements.

The retention factor k has a large effect on the allowable vapor volume. Retention can be increased dramatically by lowering the column temperature at the time of injection.

Temperature programming therefore is a very useful way of increasing the volume capacity of the column, in addition to its main function.

One of the main problems with vaporization injectors is that the volume capacity of the column may be larger than the injector is capable of handling because of its geometrical limitations. Practical experience shows that most injectors cannot handle actual (vaporised) sample volumes in excess of 1 mL without contamination effects. Assuming that the volume capacity is limited by the injector volume, this can be used as the value of Vinj. Without taking these effects into account, there is a risk of volume-overloading the injector, which in turn can lead to poor reproducibility and severe memory effects. Applying a septum purge can partly prevent these problems.

Liquid evaporation volumes

After introducing a liquid sample into a hot injector, the sample will evaporate explosively. This is followed by a huge expansion from liquid to vapor. This depends on the temperature and pressure in the injector, as well as on the molar quantity of 1 µL of sample solvent. In general an expansion factor of 200 – 1500 from liquid to sample vapor should be taken into account! After evaporation just 1 or 2 µL of sample can already fill the entire liner volume.

| Vapor Volumes of 1 µL Solvent at 250oC and 0.7 bar Inlet Pressure | |

| Solvent | Vapor volume (µL) |

|

Pentane |

250 |

| Hexane | 195 |

| i-Octane | 155 |

| Dichloromethane | 400 |

| Carbon disulfide | 423 |

| Methanol | 700 |

| Water | 1400 |

Injector Discrimination

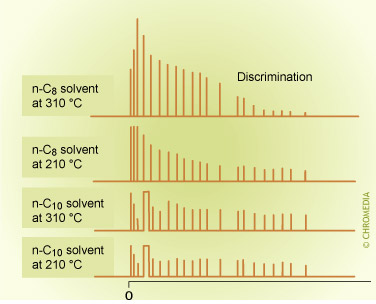

Discrimination results when the small fraction of the sample applied to the column is not representative of the original sample. This effect is more likely to occur when the boiling range of the sample components is wide.

Injector discrimination is partly due to:

- Inefficient vaporization from the syringe, which tends to leave the higher boiling components behind

- Variation in split ratio during the vaporization process. This occurs because all components do not vaporize instantaneously, and so the carrier gas contains a variable composition of sample vapor as it reaches the column entrance. The net result is that the amounts of higher boiling compounds reaching the column are relatively lower than the more volatile compounds.

Most samples for GC are in a liquid state after being dissolved or diluted in a volatile solvent. These are then introduced into the injector by using a microlitre volume syringe containing the appropriate sample volume (usually 0.1 to 1 µL). This is injected by inserting the syringe needle through a self-sealing septum comprising a thermally stable silicone rubber.

Syringe discrimination effects

Manual injection is undoubtedly one of the biggest causes of variation in practice, particularly when different operators are compared.

Although the use of autosamplers can significantly reduce human error, there are some remaining inherent problems that are associated with the injection of liquid samples into hot injectors.

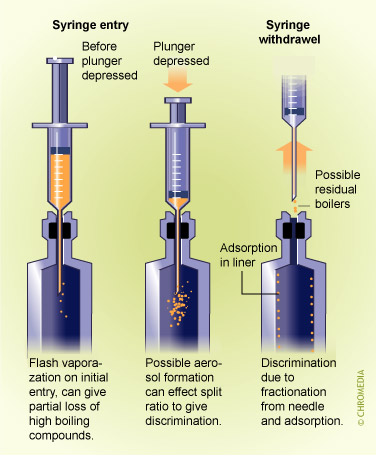

Any injection technique that involves the conversion of the sample to its vapor before it reaches the column is known as a vaporization technique. This vaporization process is usually carried out very quickly as a flash vaporization and this usually means that the syringe needle has to enter a very hot zone.

Syringe injection is inherent to a number of problems:

- Vaporisation of sample in the needle

Part of the sample that is present inside the needle can start to vaporize immediately, even before the plunger is depressed. Although this is not a problem for most samples, very high boiling components may either distill slowly from the needle, or they may vaporize and recondense in the cooler upper regions of the needle.

- Sample discrimination

Disproportionation of the sample can occur when sample components are partially retained by the syringe upon injection onto the column. This is called sample discrimination and can cause considerable error in some analyses.

- Sample transfer

Another major problem with regard to syringe handling is the transfer of the minute quantity of liquid sample to the GC in an accurate and known amount. Fortunately, the use of the internal standard procedure usually eliminates errors arising from this source.

For manual syringe handling, the following general procedure is recommended:

- Draw the required sample volume into the syringe.

- Withdraw the plunger slightly. For plunger in needle syringes this should be by approximately 1cm to leave an air gap between the bottom of the needle and the sample.

- Quickly wipe the outside of the needle with a clean tissue.

- Insert the needle into the septum and push it to the full depth. Depress the plunger and withdraw the syringe as quickly as possible. For certain applications, especially if very high-boiling compounds are involved, the repeatability can be improved by leaving the syringe in the hot injector for a few seconds after the actual injection.

Syringe handling should be consistent if a high level of precision is required, and this is best ensured by using an autosampler.

Injection needle discrimination